The RealGaz is the leading company of the technical gases and the first manufacturer of high pressure (200 and 300 bar) steel seamless gas cylinders in Azerbaijan. We are the official representative of world famous Czech trademark Vitkovice Cylinders and carry out the sales of the cylinders on the territory of Azerbaijan, Georgia, Kazakhstan, Uzbekistan, Turkmenistan, Kyrgyzstan, Tajikistan and Iran.

VITKOVICE CYLINDERS is an important member of the engineering group VITKOVICE MACHINERY GROUP, which includes more than 60 companies with a total revenue of over 1 billion EUR and employs 8,500 people around the world. The history of production of high-pressure steel gas cylinders in VITKOVITSE begins in 1906 when steel cylinders for compressed gases initially were manufactured from seamless pipes in a pipe shop. Forging of the bottoms and necks was carried out in the forging shop, heat treatment - in the tool shop, processing, testing and fitting in mechanical workshops. Processing, testing and fitting of steel cylinders were placed in a small machine-building shop in 1938. A new forging and tool shop was launched in the mid of 1942, and the old one was adapted to the forge and press shop on the production of cylinders by means of hot drawing method and started their batch production. The steel production had not been concentrated until 1956, which resulted in increased costs of transport from one hall to another. In 1981, the hardening shop was reconstructed and in 1988 - 1992 the production of 200-bar steel cylinders was upgraded comprehensively. The series production of 300-bar steel cylinders was started in 1996. A unique production line on manufacturing of steel cylinders by means of a backward extrusion method was introduced in December 2008. This manufacturing technology to produce steel tanks of such large diameters (over 267 mm) had never been used anywhere else in the world. CYLINDERS a.s (Czech Republic), VITKOVICE MILMET S.A (Poland) and CIDEGAS S.A (Argentina) as the parts of engineering group VITKOVICE MACHINERY GROUP are engaged in the production of high-pressure steel gas cylinders. All three companies work very closely together, as their production programs are mutually complemented. Thanks to this unique cooperation VITKOVICE MACHINERY GROUP is able to produce 1.5 million seamless high pressure cylinders per year.

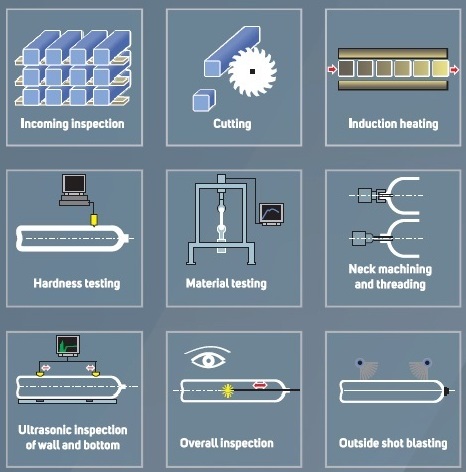

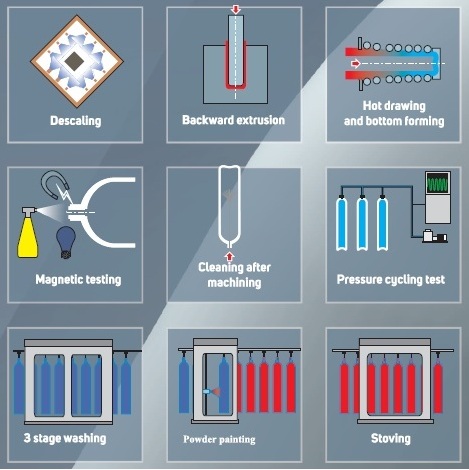

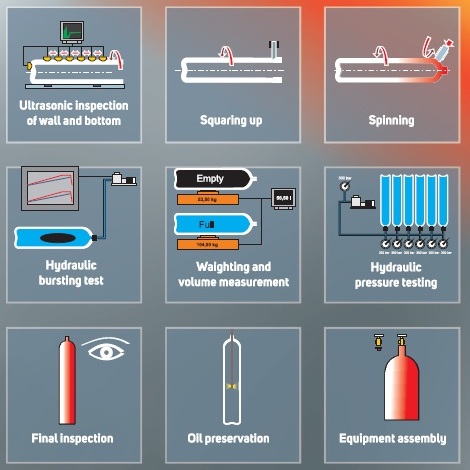

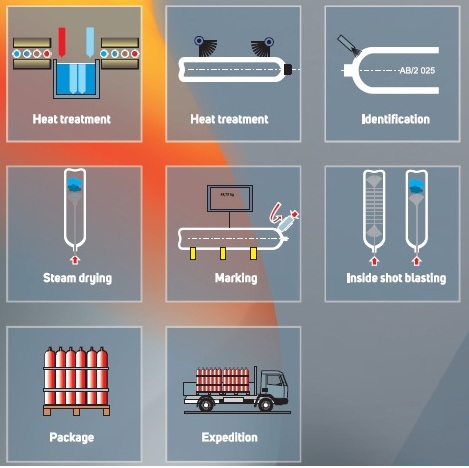

Production of high-pressure steel gas cylinders.

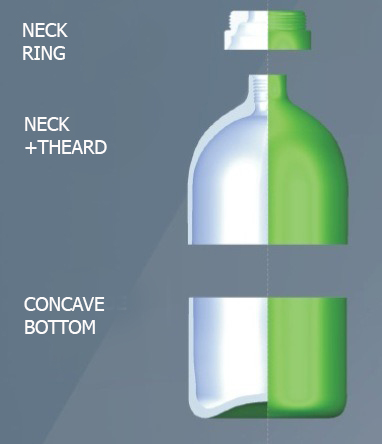

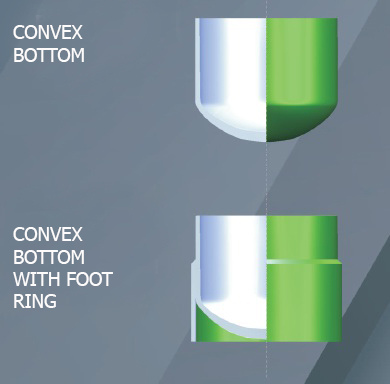

The production of high-pressure steel gas cylinders is carried out by the means of backward extrusion and hot drawing when the rolling stock is used as a raw material. This advanced production technology ensures the production of high-quality seamless high-pressure gas cylinders of low mass. In addition, our company applies the advanced technology for the manufacturing of cylinders from seamless pipes for high pressure gases. A unique technology of rotary forging is used in all our workshops to make bottom and neck of cylinders produced by this method. The product must be mechanically processed and tested in accordance with current international standards after hot forming and heat treatment.

Steel cylinders for fire extinguishing systems. Steel cylinders for food industry.

Steel cylinders for breathing, including medicine, diving, various breathing equipment. Cylinders for acetylene. NGV 2.

Steel cylinders for compressed natural gas, used as an alternative fuel for vehicles

Seamless steel cylinders. Steel cylinders for the compressed natural gas storage (monoblocks, trailers)

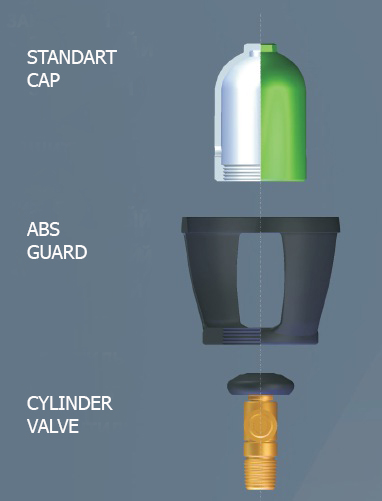

Accessories for steel cylinders. PROTECTIVE STEEL CAPS CLOSED, certified according to EN ISO 1117, are supplied in the following versions: - Galvanized - Galvanized and painted (powder coating) - With customer marking, logo, etc. PROTECTIVE COLLARS OPEN, certified according to EN ISO 1117, are supplied in the following versions: - For cylinders up to 20 liters - For cylinders up to 50 kg in multi-colored version - With the possibility of VALVE’s logo or seal application for any kind of compressed or liquefied gases, are supplied in accordance with current domestic, European and international standards and codes. HOSE RINGS manufactured by hot forging of steel billets according to the customer's own design are supplied in the following versions: - Galvanized - With customer marking, logo, etc. Our lines are equipped with professional machines for the assembly of valves and we are ready to meet our customer halfway when installing any accessories of steel cylinders.

All for gas

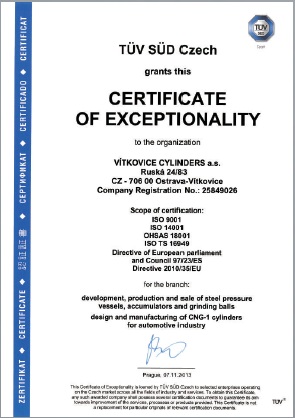

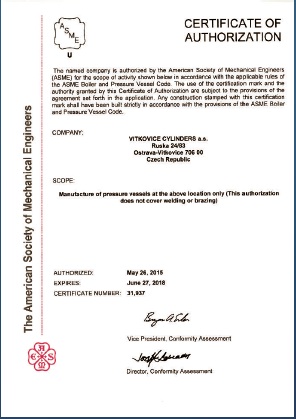

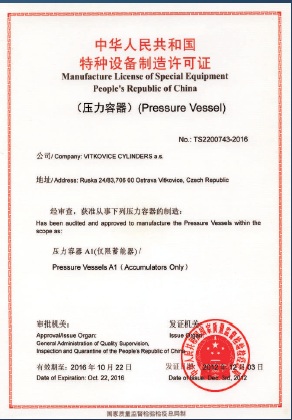

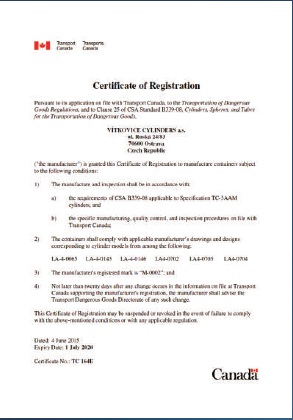

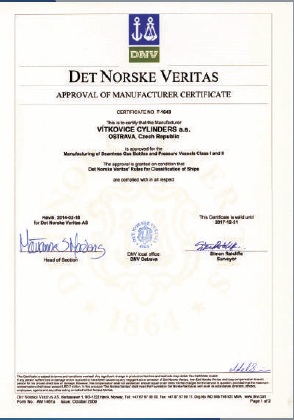

We hold the quality system certificate in accordance with ISO 9001 standard since 1994. In 2003, we successfully passed the certification process of the environmental management system in accordance with ISO 14001 standard. In 2009, we passed the certification of health and safety management system at work that meets the requirements of OHSAS 18001 standard, and in 2010, passed the certification of the quality management system in accordance with ISO / TS 16949 standard. All the mentioned above certificates were issued by the TÜV certification body. Produced high-pressure gas cylinders comply with the requirements of TPED, PED and regulations of ADR / RID, DOT-3AA, TC-3AAV, etc. Cylinders are designed and manufactured in accordance with various standards, including ISO 9809-1, ISO 9809-2, EN 1964-1, EN 1964-2, ISO 11439, ECE R110, as well as in accordance with special customer requirements, including new Russian requirements for compliance with the terms of the technical regulations. Our production qualification has been confirmed, but not limited to, by TÜV, BV, DDNV-GL, LRS, Arrowhead, HSB, RMR, etc. The production process from the beginning to the end is subjected to strict quality control. This control includes control of the source material, control of the billet during the production process and control of the final product. The control mechanism of production is based on different types of non-destructive testing that are performed in different phases of the production process. The achievement of the required mechanical properties is tested by an independent accredited testing laboratory. Quality certificates are issued for all cylinders that have successfully passed the output control.